I try to embroider on beflex (spandex)

Approximately for about one year ago, Tatyana – one of the first visitors of my blog asked me about embroidery on beflex (it still call spandex). Then I honestly answered that I never faced and don't know anything about this fabric. And here at last, I ripened before to test embroidery on this interesting jersey on the properties.

Who doesn't know and doesn't use spandex? It is known by all – of it do bathing suits, swimming trunks, sports shorts and other sportswear which is very convenient as it is capable to take any forms. Spandex is well-known that its ability to stretch in any of the directions can reach 500%! And, after it will be stretched, and then is released in the normal weakened state, it changes neither the form, nor properties even at repeated use. This material (fabric) very resistant to deformation and thanks of the Du Pont company which more than half a century presented to mankind opportunity to use this material back.

But, exactly thanks to the properties to stretch in all directions, spandex, by right, is considered one of the most difficult bases for embroidery machine. Even the glory about difficulties of work with jersey as it seems to me, grows dim before this material. Meanwhile, on it all embroider practically – here and there it is possible to see both logo, and designs, even palettes somehow I saw an embroidery. And it means, as any other embroiderers, experienced or not really will be able to make on it an embroidery. Very much I trust in it.

Technically, but only at first sight, the embroidery and preparation for it is rather simple:

• Criteria of an assessment of appearance of embroidery on spandex are directly opposite to all other fabrics – here we look how the design looks good in the stretched condition of fabric. In the loosen state fabric can go even folds round an embroidery, between objects in it, but when wearing all these clothes leaves, and the embroidery will look correctly.

• Proceeding from reasons that all clothes which are made of this material, wears in the stretched look, it turns out, as spandex needs to be stretched at hooping, and it together with the stabilizer - detachable or with invisible and pleasant to a body spanbondy (if you are able to buy it).

• To use needles stretch (ball point, ses or suk), thickness #75.

• Threads usual (#40) or any other.

So, how to make design for usual threads or to pick up from ready for an embroidery on spandex?

• The most important to try to avoid fillings. Small on the area it is possible to use still and here large it isn't desirable. They won't allow fabric to stretch naturally in wear, and the design will look deformed. The best designs – the inscriptions made on the basis of sateen (smooth surface) and drawings, executed single, untied with each other sateen. Such ones so that in these designs was a maximum of free space between embroidery elements. Lengths of stitches have to be in limits the 5-6th. It is better to avoid fine details and simple lines in design.

• Stitch density for usual threads (#40) – 0,3-0,4mm. Here it is necessary to select experimentally, proceeding from features of calculation of stitches in concrete software.

• Compensation of tightening - the standard. At me practically always put 0,2мм.

• Being guided by recommendations of John Deere who wrote that it is necessary to create design for embroidery on a spandex/lycra/elastane as well as for pique. That is, to give to external stitches a good basis in the form of frame lines (substrates):

o For sateen to 3 mm - edge run

o For sateen from 3 mm - edge run + double zigzag

o For fillings – grate under 90 degrees to a finishing layer or a full grate under 45 and 135 degrees + edge run. Density of this layer is small 2-2,5mm.

All this is quite obvious and clear, and I made here this logo:

In this design there are all types of stitches recommended and not recommended: sateen of different thickness, and fillings of different density, and even letters simple line. I tried to embroider it with the same way as got used to embroider:

- In total with the same stabilizer that I use under everything (which it was sold to me as separable, and in practice rather detachable)

- With the same method of hooping when it is important to hoop fabric that it wasn't loosen.

And, certainly, the first with what I faced – difficulties to hoop. Fabric possesses huge potential to stretching, and, as though I didn't try, it in a tambour will always sag:

Fabric possesses huge potential to stretching, and, as though I didn't try, it in hoop will always sag:

Secondly, even understanding that I need to stretch fabric in hoops, and I at all didn't put any marking on fabric, even a cross for center designation, in general to me it became unclear, in what direction and to what degree I have to pull fabric. But all the same I embroidered design and saw that here and there edges of sateen, especially with a big length of a stitch became jading, and that for stitch length from 4-4,5

mm density 0,4

mm has obviously not enough (stitches sag and from under them fabric is visible), even in the presence of frame lines of double zigzag:

In an unhooking the embroidery looks here so:

In general, it is quite good for the first time. Rare on density coverings – are perfectly draped and even stretch and here dense I really wouldn't to make heavy design. The letters embroidered with lines are normal, I didn't notice any features in them, and it is quite possible to apply.

But at once I asked a question: as far as fabric has to be stretched at hooping that it looked well at a wear? How to check it? I rummaged on the Internet and found remarkable advices of Pat Williams, when hooping the similar fabrics is enough to achieve fabric stretching in repartitions of 10-40%.

Well, and the roughness of sateen also is so obvious - parameters were picked up incorrectly of frame lines. Under the sateen a zigzag had a big length of a stitch. And here if to break it into smaller stitch the problem can be solved.

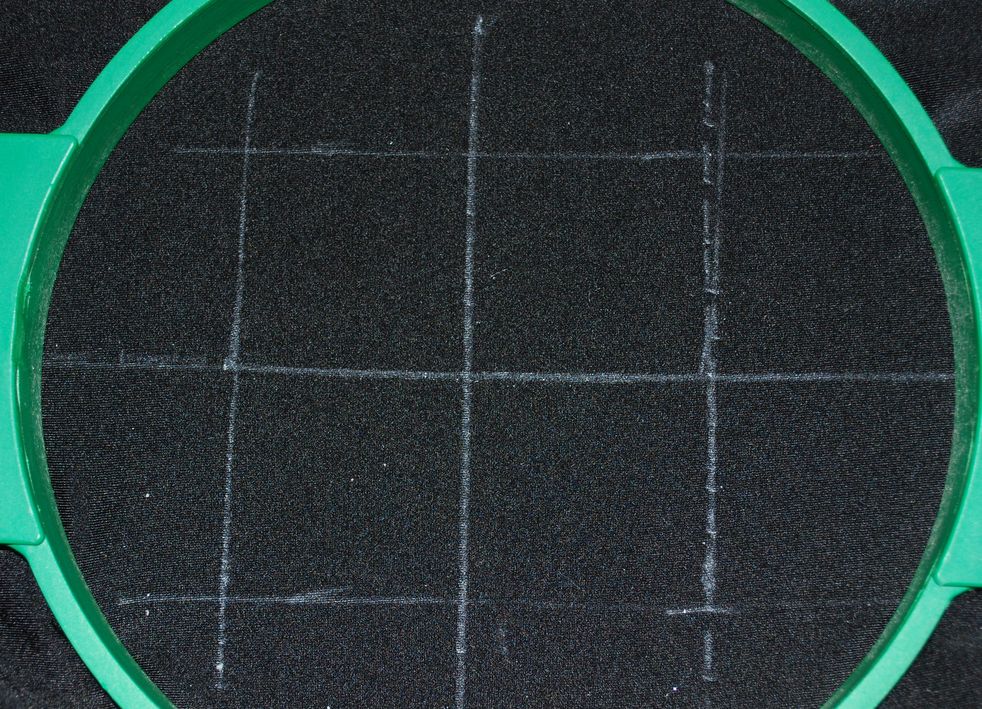

I had to make for the second test a marking on spandex in the form of not simply cross, I had to add in a marking still a square 10 x 10 cm that I could control at a hooping as evenly I stretched fabric and on how many percent. When hooping I managed to stretch fabric for 15%. That appeared for me not really simply:

I embroider corrected in parameters of frameworks design, done already slightly better, but density to thick sateen won't prevent to add:

Here it is already out of hoop fabric – gone wavy round design:

And it’s the same, but stretched on a foot – looks perfectly:

It is possible to embroider and on such fabric, it is just necessary to test that it turns out and by results to make changes to the program with standard settings. And at the same time, it is necessary to explain to clients why the embroidery on similar fabrics in a usual state looks in this way.

Recommended Comments